Precision according to your data

For more than 25 years we are designing individual tools that impress with their quality.

JoRe Werkzeugbau GmbH.

We manufacture high-quality punching tools, forming tools, follow-on tools, transfer tools, prototype tools and line tools, especially for automobile manufacturers and subcontractors.

For more than 25 years, customers, such as BMW, Mercedes Benz, Volkswagen, Benteler, Porsche, Sodecia, ThyssenKrupp and many more have appreciated JoRe tools’ precision and their processing times. The JoRe team at the Verl site ensures a high customer satisfaction and on-time productions.

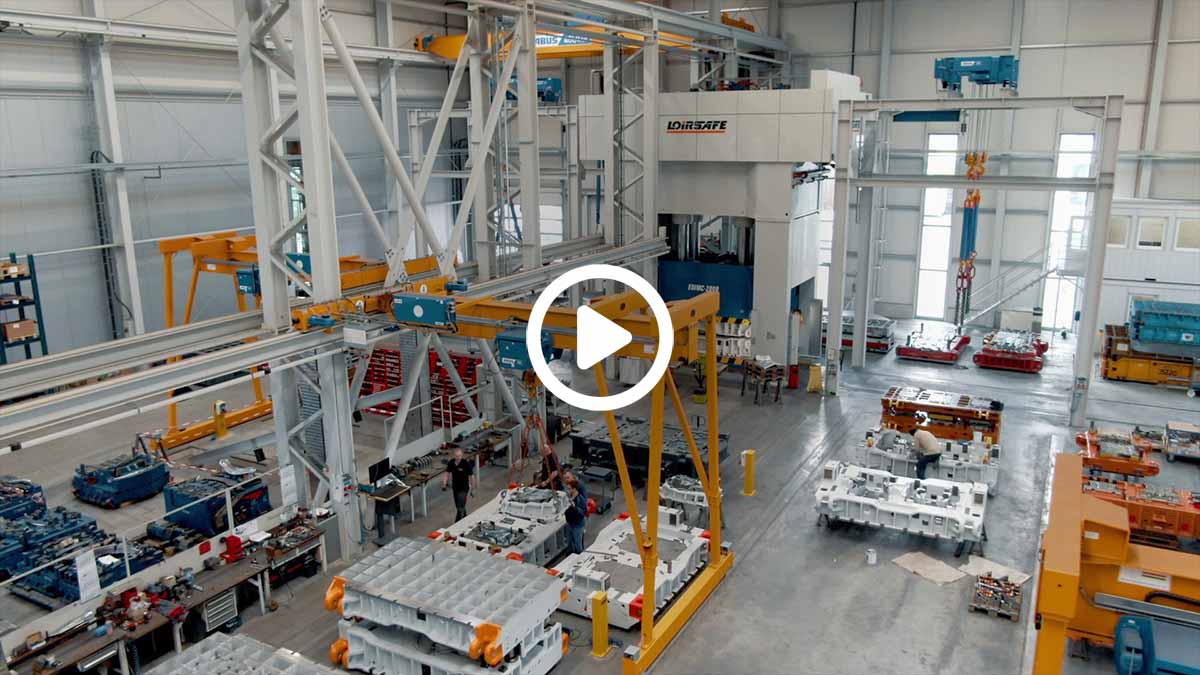

Our globally-positioned company wins you over with modern machinery and its appr. 85 employees who know their craft:

JoRe’s tool makers and cutting machine operators work with modern machines and use manual work as well. Thanks to the CAD/CAM software Tebis, our production is paperless. This is how precision tools with a weight of up to 40 tons and a range of more than 500 components are developed.

Subcontracting is another important business segment. In addition to the production of complete tools, we have long since provided our metal cutting skills successfully. For this purpose, we rely on our modern and linked up machinery.

We can fall back on the design engineering services in our ISPA Engineering design engineering office at any time. In an intensive exchange of information between the engineers from construction, production and from the customer’s side as well, we develop flexible and prompt solutions together. For the direct communication between production and design engineering, we use the Tebis system for paperless production.

Latest News

JoRe Werkzeugbau is now TISAX certified

Data protection is a key issue affecting companies in all industries these days. The protection of sensitive data is very important, especially for toolmaking companies. We are pleased that we recently received the TISAX certification. TISAX stands for "Trusted...

25th anniversary

The company JoRe Werkzeugbau celebrates its 25th anniversary this year. We would like to thank all employees, customers and suppliers for the good cooperation in recent years and look forward to the future!

A 2000T Press for JoRe Werkzeugbau

Since beginning of year 2018 we can work with our own 2000t Loire Safe pressWe are proud to have one Loire Safe press of not many on the world with imporntant components from Germany in our machine park.With a table of 5000 x 2500 we are safe for the future.

Excellent quality.

The company JoRe Werkzeugbau GmbH, founded in 1995 by Frank Johannhörster and Michael Reker, stands for quality and reliability.

This is confirmed by the DQS certificate for the management system according to DIN EN ISO 9001: 2015

Since 2023, we have been TISAX certified to ensure that confidential customer data is better protected.

| May 1995 | Frank Johannhörster and Michael Reker found JoRe Werkzeugbau GmbH nwith the company location in Rheda-Wiedenbrueck. Shop floor and production area: 600 m² |

| September 1996 | We establish our own Design Engineering Department. |

| November 1997 | Purchase of 3,000 m² of company premises in Verl |

| December 1998 | Set-up of a Department for Quality Assurance |

| September 1999 | Start of construction of the new production site in Verl with space of 1,200 m² |

| October 1999 | DIN ISO 9001 certification |

| April 2000 | Company move to Verl |

| August 2001 | Expansion of the new premises in Verl to 1,600 m² |

| January 2002 | Foundation of ISPA GbR: The Design Engineering Department which was internal to date now becomes independent |

| March 2002 | Purchase of another property of 2,200 m² in Verl |

| November 2003 | Integration of our own drawing simulation workstations (Software Autoform) |

| 2003–2007 | Period of consolidation |

| January 2007 | Expansion of office space by 200 m² as well as shop floor space by 350 m² |

| April 2008 | Benteler Automotive AG awards JoRe Werkzeugbau GmbH the prize for „Best Supplier of the Year 2007 for Toolings“ |

| August 2008 | Purchase of another property in Verl with 2,050 m² and a hall with 400 m². Thus, the land area in Chromstrasse grows to more than 7,000 m² |

| March 2009 | ISPA Engineering changes its construction software from AutoCAD to Catia V5 |

| July 2009 | Initial operation of the CNC/CAM High-performance mill center Zayer ”Tebas“ (5,000 × 3,000 × 1,100 mm) |

| May 2010 | Introduction of paperless manufacturing (TEBIS terminals in manufacturing)nInitial operation of the CNC/CAM High-performance mill center Zayer ”Memphis“ (3,000 × 2,050 × 1,100 mm) |

| August 2010 | Introduction of an ERP system. An in-house development and thus directly tailored to the requirements of tool making |

| 2011 bis 2013 | Period of consolidation |

| 2013 | Acquisition of two 5-axes machining centers:n- Grob G550T (900mm x 800mm x 1,000mm)n- Haas UMC 750 (630mm x 500mm x 500mm) |

| January 2014 | Expansion of production area and office space through the purchase of adjoining property |

| 2015 und 2016 | Period of consolidation |

| 2017 | Planning of new building with press |

| 2018 | Build new hall | Purchase 2000t press |

| 2019 | launch of new production building with 2000 sqm and a 2000to press |